- News

- 10 likes

- 4551 views

- 0 comments

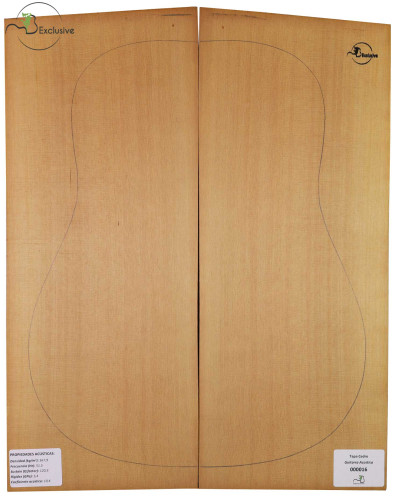

We have recently added a new section to our catalog featuring unique MB parts with audio samples, videos, and sound analysis where you can observe the main acoustic data of each soundboard.

In this initial release, we have selected 60 high-quality soundboards for high-end guitars in Alpine Spruce, Torrefied Adirondack, and Canadian Red Cedar, for both classical and acoustic guitars.

This sound analysis conducted on each soundboard will revolutionize the way we purchase wood. In addition to selecting based on appearance, from now on, you can also choose the sound profile of each piece before making a purchase.

In this article, we will delve deeper and explain in detail how to interpret all this data with the guidance of the creator of this software, Giuliano Nicoletti (Luthier and Sound Engineer), providing a series of recommendations to assist you in choosing each soundboard. Factors to consider include density, rigidity, frequency, sustain, and radiation coefficient, alongside the intended usage for each instrument. Recommended values will differ for a studio guitar versus a live performance one, whether it will be played with a pick or fingerstyle, and so on.

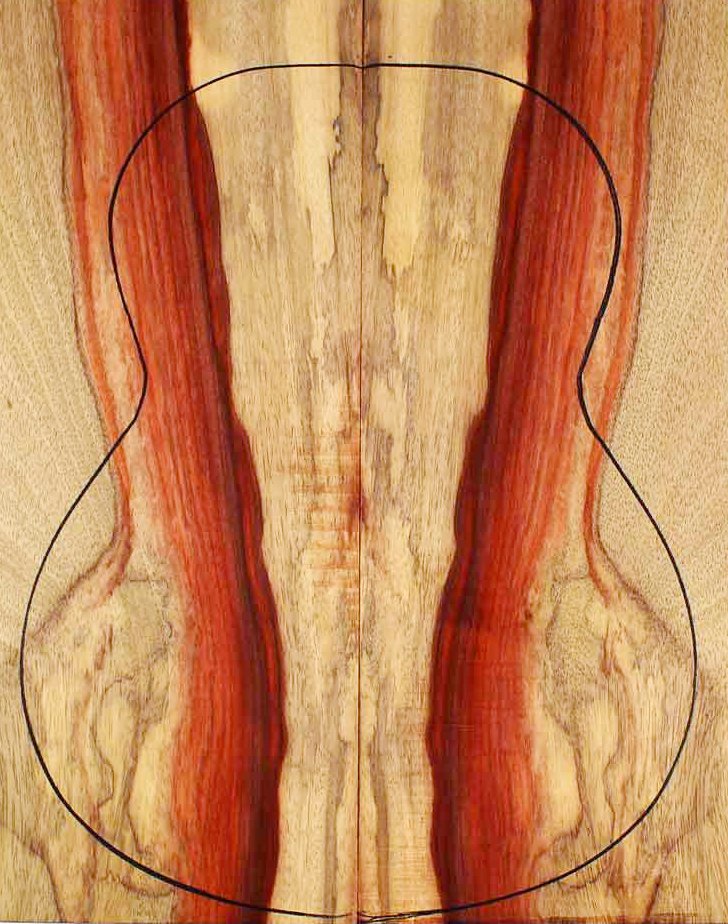

Red Cedar Classical Guitar Top MB Exclusive Nº...

Architecture of the guitar

The structure of the acoustic guitar, its body, mainly fulfills two distinct functions. First, to keep the strings in tension at a precise distance from the fretboard, available to the player to produce music; minimal movements of this geometry are allowed, as the setup of the instrument directly affects the comfort of play and the quality of the sound emitted (in terms of sound cleanliness – absence of noise, and available dynamic range).

The second function is to transmit to the soundboard the mechanical energy coming from the vibrations of the strings (transverse and longitudinal forces), to amplify the sound as effectively as possible.

These two functions are indeed antithetical; the first one requires a general strength of the structure in the longitudinal direction, to withstand the continuous tension of the strings (about 40-45 kg for a classical standard set with a scale length of 650 cm) and avoid plastic deformations throughout the whole life of the instrument. The second one requires lightness and compliance of the soundboard to transform as much of the mechanical energy provided by the strings as possible into sound.

A compromise must be accepted, and to be able to consistently choose the most convenient one it’s helpful to be able to assess the acoustic and structural performances of the instrument.

Defining the parameters

The main parameters of tone wood that are directly related to the vibroacoustic behavior of the soundboard are the density, the stiffness, the radiation coefficient, and the damping. Let’s have a close look at each single one, and how to use this data to improve the sound and performances of the instruments we build.

Resonance frequency of the first longitudinal bending mode, number of vibrations per second.

The frequency at which the sample, excited by the energy supplied by the marble, will resonate at its first longitudinal bending mode. The stiffness of the sample will be calculated at this resonance frequency, that has a strong influence on the character of its tone.

Density, the mass of an object divided by its volume.

Density is defined as the ratio between the mass and volume of a substance, and the Greek letter rho is used to describe it. The calculation of the density of a tone wood sample is simple: once the length, height and width of a sample have been measured, the volume is derived; by using a balance it is measured, and dividing the weight by the volume the density value is obtained, usually expressed in kg per cubic meter.

The first general quality of tone wood is lightness, therefore a low-density tone wood for the soundboard is almost always preferred. The strings can supply a limited amount of energy to produce sound, so that reducing the equivalent mass of the soundboard is improving the responsiveness of the guitar, and the perceived volume of sound.

Stiffness, the resistance to deformation under the action of an external force.

The rigidity of a material is the measure of its elasticity, and defines its resistance to deformation under the action of an external force. For our purposes we are mainly interested in two types of moduli:

The Young's modulus (E) describes axial elasticity, the tendency of an object to deform along an axis when opposing forces are acting along a direction normal to the object’s faces; it is often referred to simply as the elastic modulus.

The shear modulus or modulus of rigidity (G ) describes an object's tendency to shear (the deformation of shape at constant volume) when opposing forces are acting along a direction parallel to the object’s faces.

The Young’s Modulus is calculated as the ratio between the stress (the force applied) and the axial strain (the deformation of the body): E=σ/ε

The guitar maker is usually looking for a high Young’s modulus tone wood, as a stiff soundboard allows to reduce the thickness while keeping similar resonance frequencies, obtaining a lower equivalent mass and a more responsive instrument.

Sound radiation coefficient, how much energy is needed to excite the plate in vibrations.

In search of a single parameter that could summarize the ability of tone wood to transform vibrational energy into sound, already in 1963 John C. Schelleng presented in a seminal paper the simplified circuit of the main resonances of the violin, and suggested to consider the squared ratio between the speed of sound in the material and its density as a generic indicator of quality for soundboards, expressed in formula as: √(E/ρ^3 )

The acoustic radiation coefficient is a useful indicator of how much energy is needed to excite the monopole in vibrations, both above and below its resonance frequency. It is proportional to the stiffness of the sample, and to the inverse of the cube of density through a square root operation. This means that the density assumes the most important weight in the expression, and that in order to have a high radiation coefficient we need to look for lightweight tone woods.

Q factor, how long the tone wood plate will keep on ringing after being hit.

Damping is a property of viscoelastic materials, when subjected to an oscillatory force, that exhibit both elastic and viscous properties. It indicates how efficiently the energy supplied by an external stimulus is dissipated.

The damping of a resonance is often described through its Q (quality) factor: high Q values indicate low damping. The tuning fork is the most obvious example of a high Q – low

damping material: the energy supplied by percussion produces a prolonged ringing on the main resonant frequency of the fork, the A at 440 Hz. On the contrary, low Q values indicate a material with a high internal damping: an example of this type of material is rubber, which in fact is often used in panels to be glued on surfaces with the task of reducing and absorbing vibrations, which are dissipated in heat.

The damping can either be identified in the frequency domain by the resonance peak shape (the peakier, the higher the Q factor), or in the time domain as the rate of decay of the energy of an impulse (the longer the tail, the higher the Q factor).

Q factor is a critical mechanical parameter for sound production: in most cases guitar makers will look for a tone wood with high Q Factor, that will be easily activated by the strings and will maintain the ringing of the excitation as long as possible, slowly dissipating energy; other parameters of the design will take care of introducing the correct amount of damping (such as the bridge, the saddle, the bracing system, the sides and back).

The TPC measurement system

The data supplied for each specific tonewood set are measured via the TPC system, developed by Iulius Guitars. The system is based on the analysis of impulse of the recorded audio sample, obtained by a single tap of a marble rolling over the Tonewood sample, that is resting on a dedicated Jig. The parameters are calculated with the method of the free beam and logarithmic decrement, with the Tonewood sample usually excited on its first longitudinal bending mode, along the grains of the wood.

How to use the data?

An objective selection of Tonewood can therefore be carried out following at least two different approaches. The simplest and fastest involves the use of the acoustic radiation coefficient as an overall quality index that allows to graduate different soundboard stocks and choose the best ones for the specific application. The use of the sole acoustic radiation coefficient as is, has a limitation: it does not determine itself the performance of the selected boards in the final instrument, and leaves uncertainty of being able to achieve the objectives set in the design phase for the most important resonance modes.

To go further, it is necessary to also evaluate the stiffness and the damping values, in order to adapt the soundboard material to each specific application or personal needs and preferences.

The general guidelines for evaluating and selecting soundboard Tonewood properties are resumed in the table below, with the three parameters of SRC, Stiffness and Q factor divided into Low, Medium and High indicators.

As a general rule of thumb:

Density of the soundboard is the parameter that is mostly responsible of the Sound Radiation Coefficient, and together with the stiffness defines the speed of sound. It should be low for responsive guitars, medium for flatpicking guitars, high for preamplified instruments to be played on live stages (to reduce feedback sensitivity).

Stiffness of the soundboard should be high for flatpicking or preamplified instruments (to reduce sensitivity to feedback), medium for fingerpicking instruments, low for small-bodied instruments.

Q factor of the soundboard should be high fingerpicking or recording studio instruments, medium-low for flatpicking or preamplified instruments to be played on live stages (to reduce feeback sensitivity).

SRC is an indicator of the responsiveness of the soundboard; it should be high for fingerpicking instruments, medium for flatpicking instruments, low for preamplified instruments to be played on live stages (to reduce feedback sensitivity).

The suggested classification of Tonewood parameters has to be considered as a starting guide; experienced guitar builders might have different preferences or needs.

Delve into Giuliano Nicoletti's Research

Another exciting addition now available in our online store is the workshop manual tailored for guitar builders: "MASTERING THE SOUND OF THE ACOUSTIC GUITAR." This manual elucidates the workings of both classical and acoustic guitars, detailing how to shape their sound and measure it in a simple and repeatable manner.

From the technical evaluation and selection of woods to fine-tuning the instrument's performance during construction or addressing acoustic issues in a finished instrument, this manual covers it all.

It serves as the perfect choice for delving into the fantastic realm of acoustic measurements and enhancing the sonic signature and performance of any type of acoustic and classical guitar. It caters to guitar builders, repair workshops, and maintenance professionals alike, featuring 160 pages filled with full-color photographs, illustrations, and graphics.

(1).jpg)