- News

- 16 likes

- 785 views

- 0 comments

Varnishing is an essential part of building and finishing electric guitars. It not only acts as a protective barrier against external factors like humidity and temperature changes, but also enhances the natural beauty of the wood, influencing the instrument's resonance and tone.

Choosing the right varnish, as well as applying it correctly, is key to bringing out the unique characteristics of each type of wood. This allows you to highlight its grain, colors, and textures while maintaining the instrument’s original sound and ensuring its durability.

In this article, we will analyze the varnishing process for some of the most common woods used in electric guitar construction, detailing their properties and offering recommendations on the best varnish for each one.

Get to know the types of wood and their ideal varnish

There are various types of wood used in the construction of electric guitars, and each requires a specific type of varnishing to highlight its unique characteristics.

The varnishing process not only protects the wood, but also affects the instrument’s aesthetics and tone. From open-grain woods like ash to denser woods like mahogany, each wood type has particular needs that must be addressed to ensure the best finish and maximum resonance.

Learn about the ideal varnishes for some of the most common woods in electric guitars.

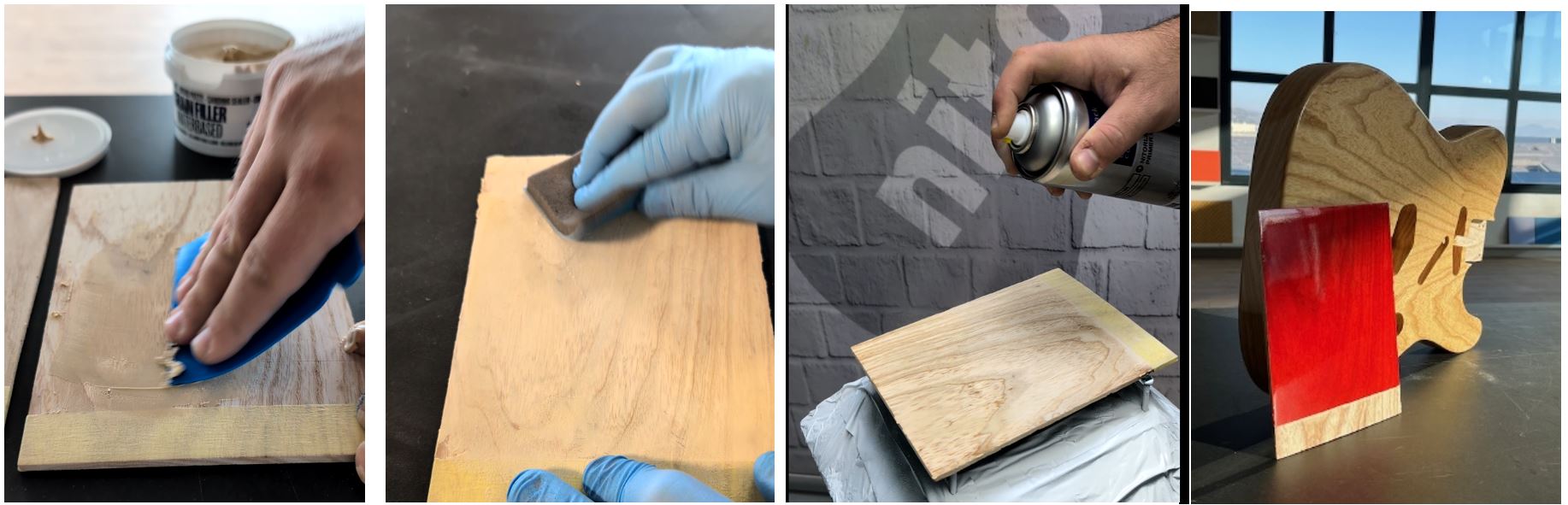

Finish for Ash

Ash is a widely known wood for its use in Fender guitars. Its resonance, light grain, and tonal range from beige to golden brown make it a very popular wood in electric guitars. It has large pores that should be sealed prior to varnishing; otherwise, it will be costly to close the pores with varnish layers.

Varnishing Process Outline

1. Sealing the pores

- Apply Nitorlack Grain Filler (Natural) as it resembles Ash.

- Let it dry completely.

- Sand with P240 and P400 to remove excess product.

2. Choosing the varnish

- Opt for nitrocellulose, following the tradition of 50s and 60s Fender guitars.

- You can also use other Nitorlack varnishes with good results.

3. Applying the Primer

- Apply Nitorlack Primer as a base.

- Apply layers with a 24-hour interval between them.

- Sand between layers.

- Apply at least 2-3 layers until a smooth surface is achieved.

4. Final finish

- Apply translucent color (optional) (e.g., red or Butterscotch).

- Finish with Nitorlack Lacquer (gloss or matte) with a 24-hour interval between layers.

- If polishing is necessary, wait two weeks before the final polish.

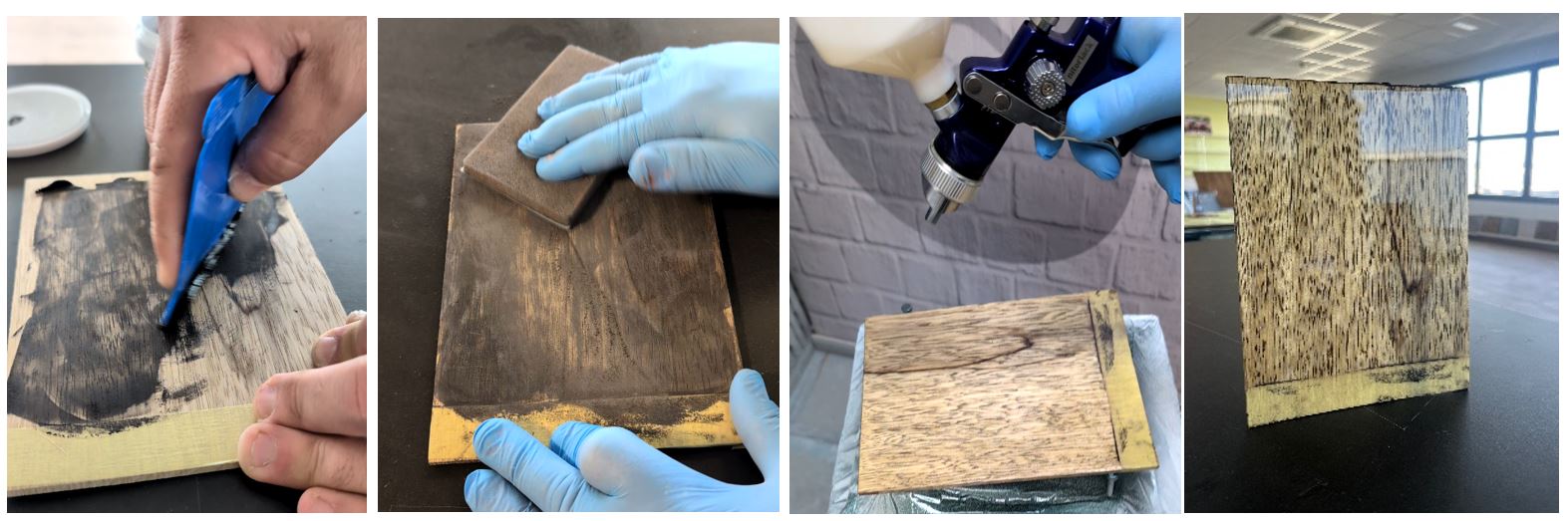

Finish for Mahogany

Mahogany is one of the most traditional woods used in musical instrument construction, widely used by Gibson in all its models. Its reddish color and medium to high density provide a unique tonal warmth and visual beauty. Like Ash, Mahogany has large pores that must be sealed before varnishing, helping to achieve a finer finish with less product.

For this case, we’ve chosen a water-based glossy finish to introduce this eco-friendly option, an alternative to solvent-based finishes that also offers excellent performance without odors. It is a single-component product that behaves similarly to nitrocellulose.

Varnishing process outline

1. Sealing the pores

- Apply Nitorlack Grain Filler (Mahogany) as it resembles Mahogany.

- Let it dry completely.

- Sand with P240 and P400 to remove excess product.

2. Choosing the varnish

- Opt for NitorAqua due to its eco-friendly benefits and good performance.

- You can also use other Nitorlack varnishes with good results.

3. Applying the Primer

- Apply NitorAqua Primer as a base.

- Apply layers with a 24-hour interval between them.

- Sand between layers.

- Dilute 20% with water.

- Apply at least 2-3 layers until a smooth surface is achieved.

4. Final finish

- Finish with NitorAqua Lacquer (gloss) with a 24-hour interval between layers.

- Dilute 20% with water.

- If polishing is necessary, wait two weeks before the final polish.

Finish for Black Limba

Black Limba is an exotic wood widely used in musical instruments for its beauty. It has a tonal range similar to Mahogany, but its color is lighter with dark lines.

It has a grain similar to Mahogany, and typically, the pores are filled with black filler to highlight the beauty of the grain.

In this case, we’ve chosen NitorPOL Polyurethane Lacquer Gloss to enhance the grain of Black Limba with a high-gloss finish.

Varnishing process outline

1. Sealing the pores

- Apply Nitorlack Grain Filler (Black), which blends well with the black grain of the wood.

- Let it dry completely.

- Sand with P240 and P400 to remove excess product.

2. Choosing the varnish

- Opt for Polyurethane to enhance the beauty and depth of the wood.

3. Applying the Primer

- Apply NitorPOL Primer as a base.

- Follow product and catalyst mixing ratios 2:1, adding 10% solvent.

- Apply layers with a 24-hour interval between them.

- Sand between layers.

- Apply at least 2-3 layers until a smooth surface is achieved.

4. Final finish

- Finish with NitorPol Lacquer (gloss or matte) with a 24-hour interval between layers.

- Follow product and catalyst mixing ratios 2:1, adding 10% solvent.

- If polishing is necessary, wait two weeks before the final polish.

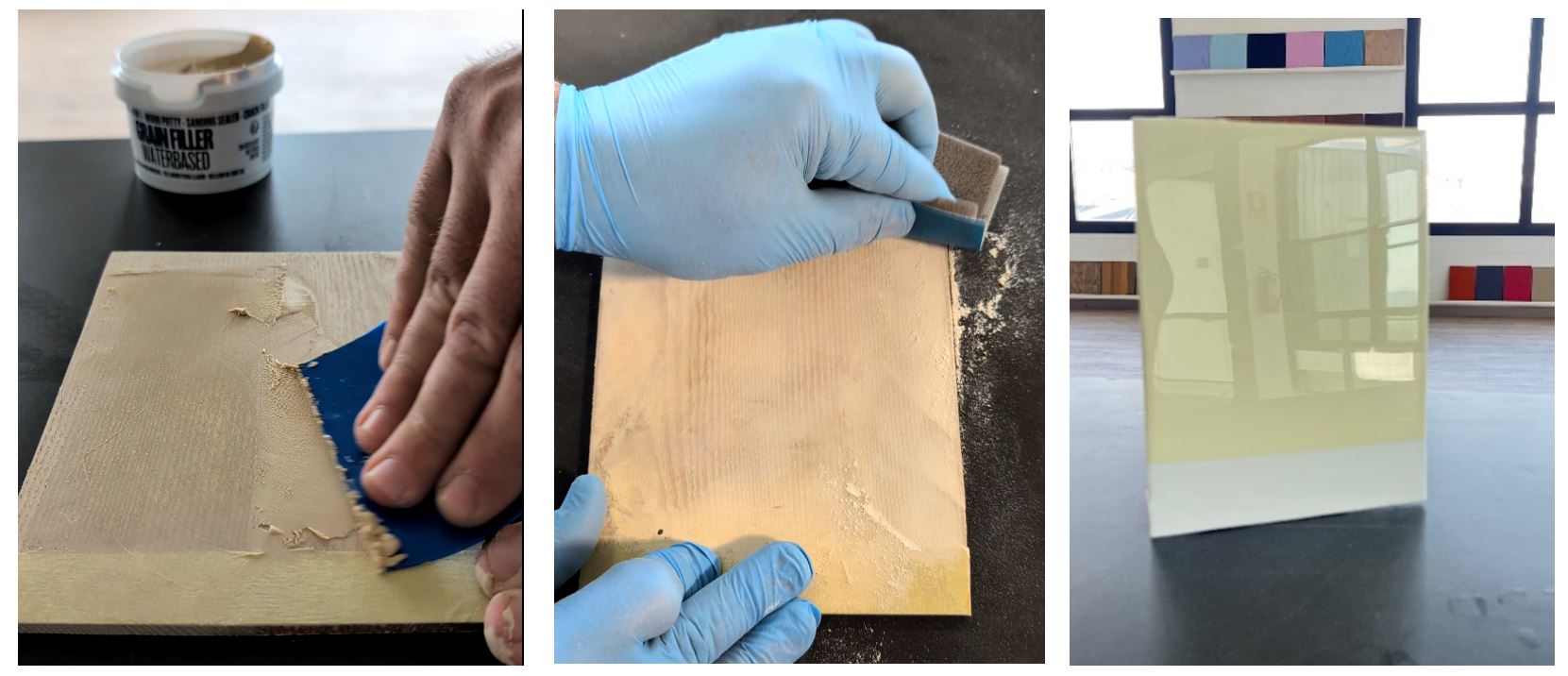

Finish for Ayous

Ayous is a tropical wood, softer than other woods used in instruments, with a smooth texture and light color. It doesn’t have marked grain or special beauty, so it is often used in solid-color electric guitars.

For this case, we’ve chosen a solid nitrocellulose process with a white base that enhances the color vibrancy and easily covers the wood’s pores.

Varnishing process outline

1. Sealing the pores

- Apply Nitorlack Grain Filler (Natural).

- Let it dry completely.

- Sand with P240 and P400 to remove excess product.

2. Choosing the varnish

- Opt for Nitrocellulose for a solid finish due to the lack of grain visibility in the wood.

3. Applying the White Primer

- Apply NitorLACK Primer White as a base.

- Sand between layers with P400.

- Apply layers with a 24-hour interval between them until the wood’s pores are completely covered.

- Apply at least 2-3 layers until a smooth surface is achieved.

4. Color

- Apply the color of your choice, in this case, Nitorlack Surf Green.

- Apply at least 2-3 layers of color to fully cover the base.

- Sand between layers with P400 and wait 24 hours between applications.

5. Final finish

- Finish with Nitorlack Lacquer (gloss or matte) with a 24-hour interval between layers.

- If polishing is necessary, wait two weeks before the final polish.

Finish for Sassafras

Sassafras is known for its distinctive aroma and grain. Due to the scarcity of Ash wood for electric guitars, Sassafras can be a good substitute for its tone and visual appeal. The varnishing process is very similar to that of Ash.

Varnishing process outline

1. Sealing the pores

- Apply Nitorlack Grain Filler (Natural).

- Let it dry completely.

- Sand with P240 and P400 to remove excess product.

2. Choosing the Varnish

- Opt for Polyurethane for a solid finish due to the wood’s lack of visual appeal.

3. Applying the White Primer

- Apply NitorPol Primer White as a base.

- Sand between layers with P400.

- Apply layers with a 24-hour interval between them until the wood’s pores are completely covered.

- Apply at least 2-3 layers until a smooth surface is achieved.

4. Color

- Apply the color of your choice, in this case, NitorPol Vintage White.

- Apply at least 2-3 layers of color to fully cover the base.

- Sand between layers with P400 and wait 24 hours between applications.

5. Final finish

- Finish with NitorPol Lacquer (gloss) with a 24-hour interval between layers.

- If polishing is necessary, wait two weeks before the final polish.

How to choose the perfect varnish for your electric guitar

The varnishing process is as essential as it is artistic in creating electric guitars. Each wood has its own characteristics, and when properly highlighted by varnish, they can transform an instrument into a work of art both in sound and appearance.

Selecting the type of varnish and the application technique are crucial for achieving a durable and visually appealing finish. This personalized approach ensures that each guitar, regardless of the type of wood used, retains its essence and shines with its own light.